Product Pictures:

Brief Description:1. Application: For seal or connect of pipe/tub-e lines 2. Material: 304,304L,316,316L,carbon steel or other material on request 3. Standard: ANSI,DIN,JIS,BS,EN1092-1 4. Size: DN15 (1/2") to DN5000 (200") 5. Type: Threaded Flanges, Socket Welding Flanges, Blind Flanges, Other Flanges

Brief Description:1. Application: For seal or connect of pipe/tub-e lines 2. Material: 304,304L,316,316L,carbon steel or other material on request 3. Standard: ANSI,DIN,JIS,BS,EN1092-1 4. Size: DN15 (1/2") to DN5000 (200") 5. Type: Threaded Flanges, Socket Welding Flanges, Blind Flanges, Other Flanges

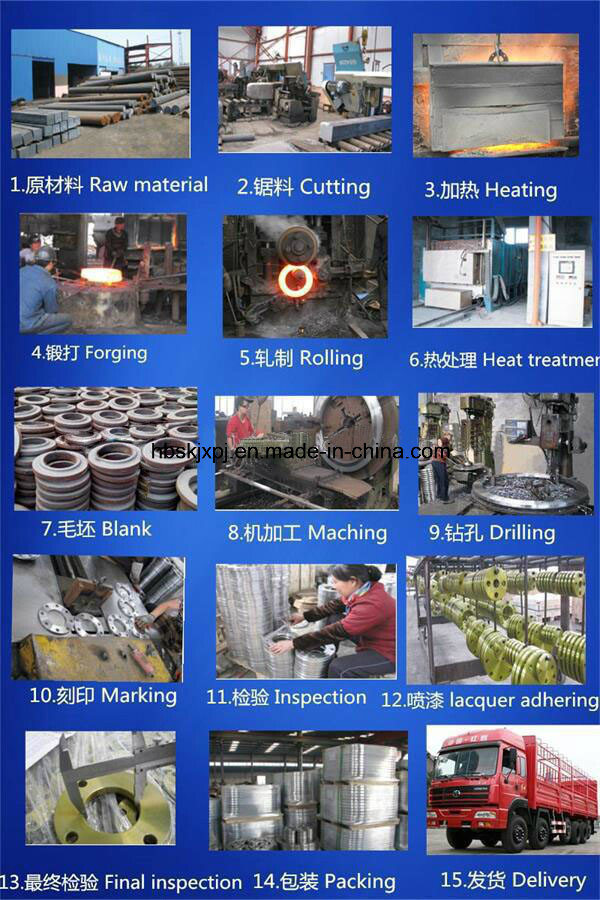

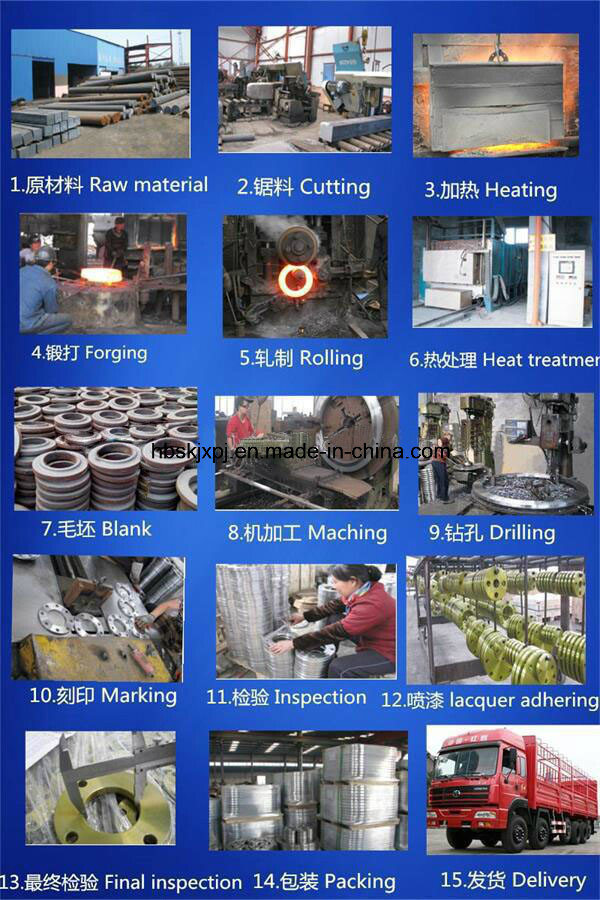

Production Flow Chart:

Brief Description:1. Application: For seal or connect of pipe/tub-e lines 2. Material: 304,304L,316,316L,carbon steel or other material on request 3. Standard: ANSI,DIN,JIS,BS,EN1092-1 4. Size: DN15 (1/2") to DN5000 (200") 5. Type: Threaded Flanges, Socket Welding Flanges, Blind Flanges, Other Flanges

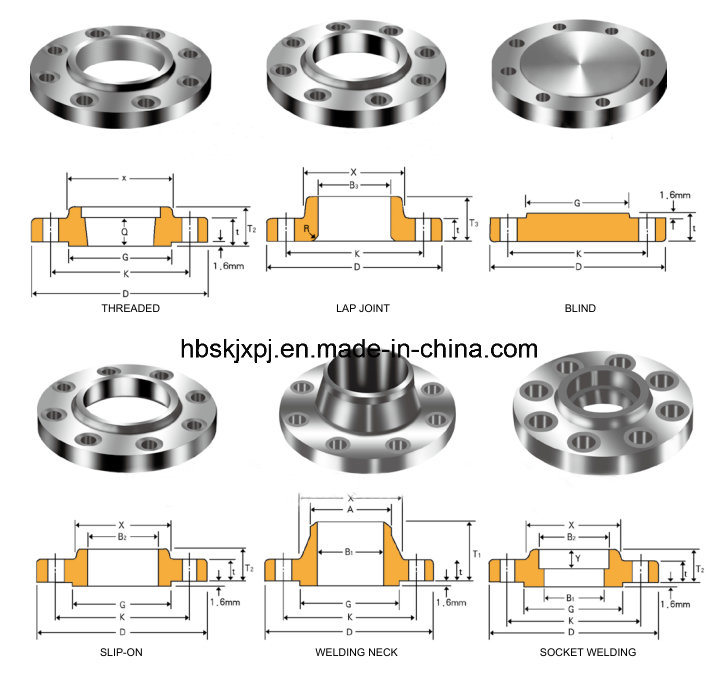

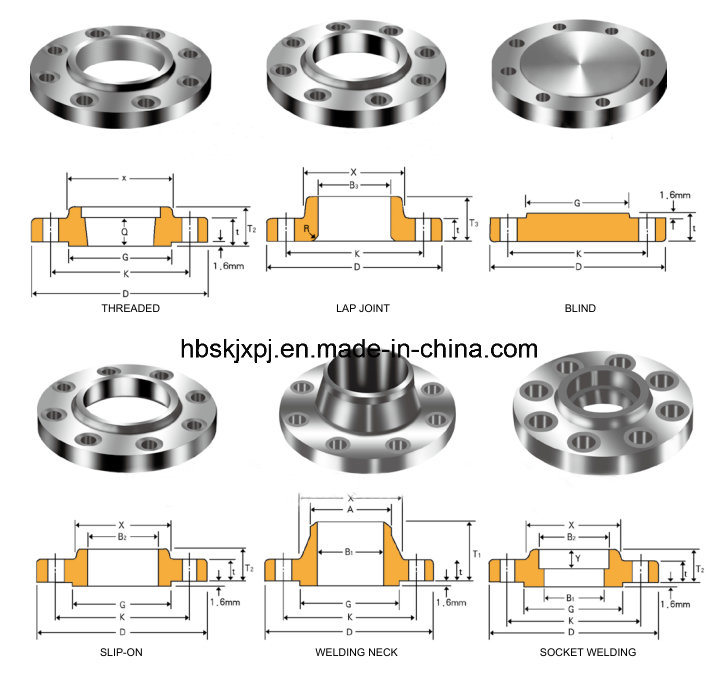

Brief Description:1. Application: For seal or connect of pipe/tub-e lines 2. Material: 304,304L,316,316L,carbon steel or other material on request 3. Standard: ANSI,DIN,JIS,BS,EN1092-1 4. Size: DN15 (1/2") to DN5000 (200") 5. Type: Threaded Flanges, Socket Welding Flanges, Blind Flanges, Other Flanges | Flange Materials | Carbon Steel: ASTM A105. ASTM A350 LF1. LF2, CL1/CL2, A234, S235JRG2, P245GH | ||||||

| P250GH, P280GHM 16MN, 20MN ,20# | |||||||

| Stainless Steel: ASTM A182, F304/304L, F316/316L | |||||||

| Flange Types | Slip On Plate Flange/Plate Flange , Slip On Hub Flange/Bossed FF/RF/RJ(ring-joint) | ||||||

| Welding Neck Flange/WN flange/ Loose Flange/Lapped Flange /Backing Flange | |||||||

| Blind Flange/Blank flange, Lap Joint Flange /LJ Flange FF(flat face) RF(raised face) | |||||||

| Socket Weld Flange/SW Flange Threaded Flange/Screwed Flange | |||||||

| Loose Flange/Lapped Flange Backing Flange RTJ /o-Ring | |||||||

| Custom Flange/Special Flange Hot/Cold/Electro Gavanized Flange | |||||||

| Standards | ANSI/ASME/ASA B16.5 FLANGES, ANSI B16.47 A/B FLANGES | ||||||

| JIS B 2220 FLANGES, KS B 1503, DIN SERIES, UNI, EN1092-1, BS4504 | |||||||

| BS 10 TABLE D/E/F FLANGES, SANS 1123 FLANGES/SABS 1123 | |||||||

| GOST12820-80/GOST12821-80, NFE29203/NS/AS/ISO/AWWA FLANGES | |||||||

| Pressure & Ratings | 150LBS, 300,600,900,1500,2500 ANSI, ASA B16.5 | ||||||

| PN6 PN10 PN16 PN25 PN40 PN64-DIN/UNI | |||||||

| PN6 PN10 PN16 PN25 PN40 PN63-EN1092-1/BS4504 | |||||||

| PN0.6Pa, PN1.0Pa, PN1.6. PN2.5,PN4.0-GOST12820-80 | |||||||

| PN0.6Pa, PN1.0Pa, PN1.6. PN2.5,PN4.0, PN6.3. -GOST12821-80 | |||||||

| 600kPa, 1000.1600.2500.4000.-SANS 1123 | |||||||

| 5KG, 10KG, 16KG, 20KG, 30KG, 40KG-JIS B2220/KS B1503 | |||||||

| TABLE D, TABLE E ,TABLE F-BS 10, AS2129 | |||||||

| CLASS D, CLASS E, CALSS F, AWWA C207 | |||||||

| Surface Treatment | Rust Prevention , Black Paint Coating or Phosphating Treatment with Black Color | ||||||

| Varnish Paint Coating, Varnish Oil Coating, | |||||||

| Electro Galvanizing Coating (Cold Galvanizing, Color Golden or silvery white, Coating thickness 20~30μm) | |||||||

| Hot Dip Galvanizing Coating (Coating Thickness 200μm around) | |||||||

| Technical | Forging | ||||||

| Application | Water works, Shipbuilding industry, Petrochemical & Gas industry, Power industry, Valve industry | ||||||

| and general pipes connecting projects etc. | |||||||

| Inspection | Quality Control System-Well Equipments and Machinery-Well Workers and Engineers | ||||||

| Packing | Wooden Pallets or Wooden Cases or As Customers' Requirements | ||||||

| Payment Terms | L/C Or 30 % Advance By T/T and The balance Will be Paid After the copy of B/L | ||||||

| Delivery Time | 30 Days after the Advance or the L/C | ||||||

| After-Sales Service | Orders and Products Tracking System | ||||||